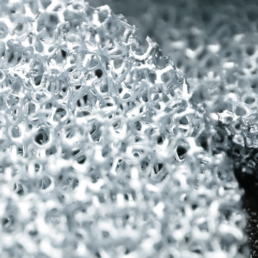

90% Air

Alloy foams are used as high-efficiency catalysts, electrolyzer cathodes, and burner substrates. Our customers say it works like magic – even though most of it is void!

Why

Metal Foam.

Save. Energy. Resources. CO2. Time to change is now - the challenge is how to make it affordable. With our customers, Alantum develops mind-boggling, ready-to-use, drop-in, catalyst solutions and energy materials to make process intensification a reality. We help change the total cost of ownership by just changing one single screw: Metal foam.

30%

Energy Savings

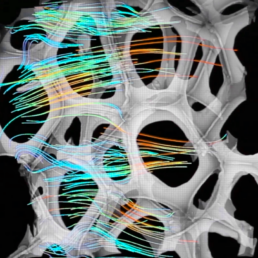

Low pressure drop, high heat and mass transfer rates change your energy footprint for good.

2x

Lifetime Gain

Crush strength, corrosion and attrition are history – when rocket-steels are used terrestrially.

5%

Feedstock Savings

When good productivity and high yield unite, something great happens.

50.000

m2/L Surface Area

Foam washcoated with catalyst carriers such as AlOx or TiOx display unrivalled volumetric activity.

20%

More Throughput

The combination of 90% void and super high activity enable a boost in productivity.

Zero

System Changes

You don’t change a single screw, but one: Alantum drop-in technology.

Fields

Applications.

We believe that significant and sustainable technology changes are necessary to meet the global energy and resource challenges. Our mission is to help you succeed and boost your total cost of ownership.

Do ask how metal foams can offer a breakthrough for your application.

Heterogeneous Catalysis

Extensive data proves that a process built around or retro-fitted to incorporate alloy foam-based catalysis works better, boosting efficiency and reducing carbon footprint. Existing reactors can be made more efficient – and new process designs simply revolutionary.

- Structured catalyst carriers

- Metal foam pellets for drop-in fixed bed solutions

- Patented filling techniques

- Structured coated catalysts

Energy

Materials

Hydrogen, CO2-valorization and electrification will play pivotal roles in the global energy transition. Decades ago, Inco/Alantum supplied high purity Nickel foam for NiMH batteries. Our sister company KEMCO is one of the largest producers of Nickelsulphate, a key raw material for Li-Ion Batteries. Currently we focus on next generation structured electrodes for electrolyzers as well as fuel cell components. What’s next?

- Structured electrodes

- High-surface Ni and NiMo Foam

- High-conductivity Ag and Cu foams

- Combustion media – for high temperature environments

Tailored

Solutions

In close collaboration with our customers we develop tailored solutions and processes. Here, the versatility of Alantum’s technology toolbox is key.

- Agile product design & engineering

- Shaping foam for mass manufacturing

- Process development: From rapid prototyping to scaled production lines